Air Driven Air Pressure Amplifiers

SCI Sharp Controls offers a line of air amplifiers from Hydraulics International, a trusted manufacturer of high-quality air amplifiers for various industrial applications.

Our selection of air pressure amplifiers includes various models designed for different applications, such as cooling, drying, and conveying. These amplifiers use compressed air to generate high-pressure output, making them ideal for tasks that require powerful airflow. Compact and easy to install, they offer a cost-effective alternative to traditional air-powered equipment.

How do our Hydraulics International air amplifiers work? They operate using the principle of differential areas. Like any air tool, they operate from a single shop air connection for most applications. The air used for cycling exhausts through the muffler provided, or may be piped out of the area. The rest of the air is compressed to a higher pressure output. When output demand stops, the unit will stall in a force balanced condition consuming no power nor generating any heat. When output demand resumes, the unit automatically responds and cycles at the rate needed to meet that demand, up to the units capacity. Output Flow Reaches Maximum as the air amplifier’s output pressure approaches the plant air input pressure. Output Flow Drops to Zero as the unit reaches theoretical stall. This value is estimated by multiplying input pressure x the last digit of the model number, e.g. model 5A-DS-5 with 100 PSI (6.9 BAR) plant air input will stall at approximately 500 PSI, model 5A-DS-2 at approximately 200 PSI (13.8 BAR). In practice however, controlling the maximum pressure desired is usually done with an external control.

Installation and Controls

Although there are a number of options for controlling these air pressure amplifier units, a final recommendation will be based on how the high pressure output air is to be used. Perhaps the most common type of control is that similar to a conventional air compressor:

- Amplify the air into a receiver tank, ASME coded if permanently mounted.

- Provide a safety relief valve at maximum rated tank pressure.

- Provide a pressure switch* set to stop the air amplifier unit at about 95% of safety relief valve setting.

- Provide an air or gas regulator (reducing valve) on the tank output set at the minimum usable amplified air pressure for the application.

* The pressure switch need not be electrical. Instead, the HII series of PCV valves performs this function in one simple unit with no electrical input required.

If you want to order an air amplifier from us, you can contact us at (704) 394-1395. Our support staff can answer any questions you may have about our Hydraulics International product line and assist you with your order. You can also reach us via email at info@sharpcontrols.com.

5A-DS-2

|

EFFECTIVE AREAS (IN)

|

BOOST |

MAXIMUM

PRESS. (PSI) |

||||||

|

Model

No. |

Wt.

(lbs.) |

Drive Stroke

|

Boost Stroke

|

Drive

Section |

Boost

Section |

|||

|

Down

|

Up

|

Down

|

Up

|

|||||

|

5A-DS-2

|

36

|

51.91

|

51.91

|

25.35

|

25.35

|

202.8

|

150

|

300

|

5A-DS-5

|

EFFECTIVE AREAS (IN)

|

BOOST |

MAXIMUM

PRESS. (PSI) |

||||||

|

Model

No. |

Wt.

(lbs.) |

Drive Stroke

|

Boost Stroke

|

Drive

Section |

Boost

Section |

|||

|

Down

|

Up

|

Down

|

Up

|

|||||

|

5A-DS-5

|

30

|

25.95

|

25.51

|

5.41

|

4.97

|

24.1

|

150

|

1250

|

3A-SS-2.5 / 3A-SS-4

|

EFFECTIVE AREAS (IN)

|

BOOST |

MAXIMUM

PRESS. (PSI) |

||||||

|

Model

No. |

Wt.

(lbs.) |

Drive Stroke

|

Boost Stroke

|

Drive

Section |

Boost

Section |

|||

|

Down

|

Up

|

Down

|

Up

|

|||||

|

3A-SS-2.5

|

7

|

7.065

(Single Acting) |

-

|

2.540

|

-

|

2.66

|

150

|

400

|

|

3A-SS-4

|

7

|

7.065

(Single Acting) |

-

|

1.538

|

-

|

1.60

|

150

|

675

|

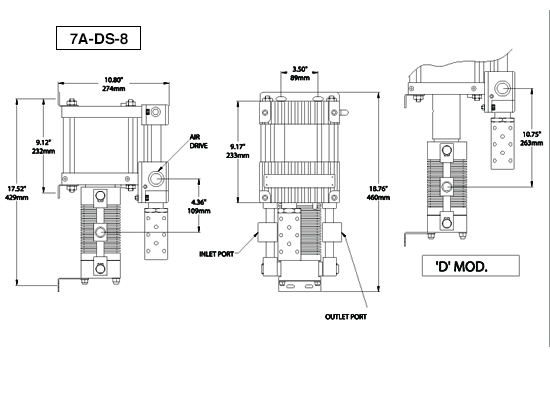

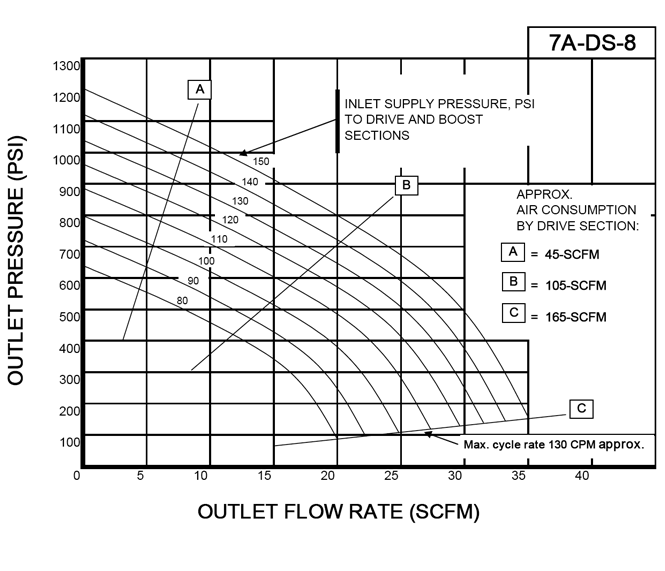

7A-DS-8

|

EFFECTIVE AREAS (IN)

|

BOOST |

MAXIMUM

PRESS. (PSI) |

||||||

|

Model

No. |

Wt.

(lbs.) |

Drive Stroke

|

Boost Stroke

|

Drive

Section |

Boost

Section |

|||

|

Down

|

Up

|

Down

|

Up

|

|||||

|

7A-DS-8

|

50

|

---

|

---

|

---

|

---

|

41.4

|

150

|

1250

|